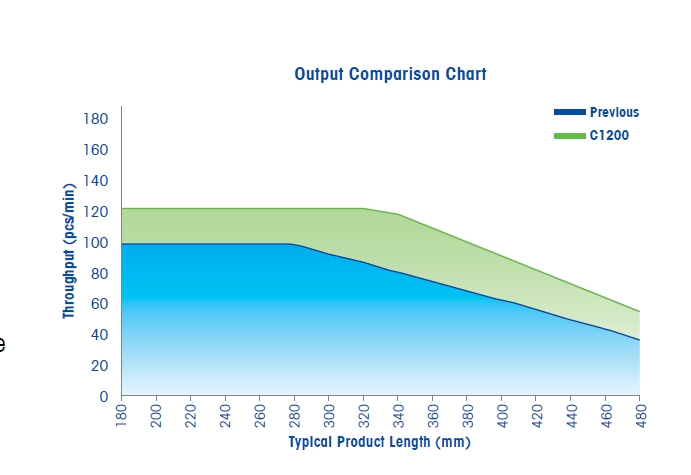

DBOX Platform – Higher Output

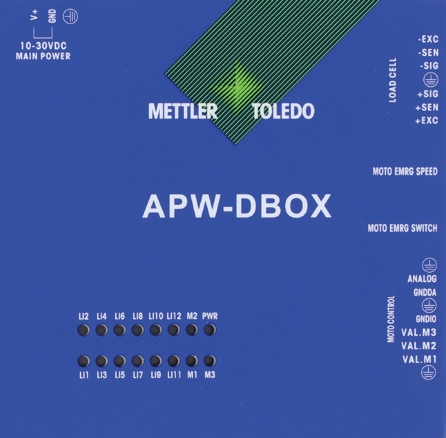

Combining reliability and latest DBOX weighing

platform into a compact system, C1200-40/100 Series

Caseweigher offers state-of-the-art dynamic weighing

technology, covering a weighing range up to 100 kg –

with amazing throughput and unprecedented accuracy.

METTLER TOLEDO has developed the ESP (Equipment

Safety Process) to ensure the equipment meets the

safety needs of the customers around the world. We

build safety into our equipment and have qualified

our design personnel in the practice of both USA and

Europe safety standards.

Ideal for industry application, designed for

dynamic weighing with higher processing speed.

MT Load Cell – OIML Certified

Top quality load cell for best

performance, guarantee a precise

measurement.

Safety – More than CE Certified

ESP (Equipment Safety Process) to satisfy

global safety requirement from both USA

and Europe.

Efficiency – 5.7" Touchscreen

Enables multiple languages HMI, less

effort in training and quick access to

menu.

Weighing terminal

• 40 products memories

• 5,7" high resolution color touchscreen

• Languages: English, Vietnam, Simplified Chinese, Traditional Chinese

Global safety

• Emergency stop as standard

• CE compliance

• Guards appropriate for the application

• Safety circuits designed-in as required

• Safety with pressurized devices

• All rejecters are guarded with, at minimum, a shield-guard

Options

• Fieldbus interface (incl. Modbus, Profibus-DP, Ethernet/IP)

• USB storage for individual weight data

• Statistics program (PrintStick, ticket printer)

• Reject verification (countercheck)

• Pressure monitoring device

• Weight data interface: RS232, Ethernet

• Rejecting devices (roller path, pusher)